WebFineblanking is a specialized metal-forming process that combines cold extrusion and stamping technologies to produce parts that cannot be made by other stamping methods. Jagemanns fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, and automotive industries. Because of the near-zero clearance requirements for fine blanking dies, we can produce parts within very narrow tolerances, avoiding the need for many secondary processes. Sipxmach is fine blanking companies in China. entirely new technical and commercial opportunities. Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance. In the beginning, we focused on international trading. Copyrights 2022, All rights reserved | CSR Policy Design & Developed by Clasticon. The process requires a triple-action fine-blanking press. The higher the production volume, the greater the economic benefits of  We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Novitek Fine Blanking is a leading supplier of premium backplates for braking systems in passenger cars, vans and truck applications throughout Europe, America and Asia. approach and an awareness of interdependencies to develop a production

104 national way, only 800m away from expressway exit, 20km Wenzhou Airport. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. "acceptedAnswer": {

We are manufacturer of high performance lubricants used in all range industrial equipment Korea.Our company have long and quality experiences lubricating cicle Korea.From beginning last year we started exporting to foreign countries with our competitive price& quality.This trying Telephone82-2-20272501~6AddressRm# 915, Woolim Lions II-Cha, 680, Gasan-Dong. We are committed to manufacturing products that exhibit an outstanding level of quality and proving a service level commitment that surpasses your expectations. progressive die limited space it is almost impossible to design the precision tooling to apply three force on sheet metal. In fine blanking, the clearance between the punch and the die is smaller and the blanking is performed at slower speeds. "mainEntity": [{

This approach gives us the flexibility to deliver to varying customer requirements and volumes while maintaining a high service level. At Petersen Precision, we utilize the fine blanking process to achieve excellent dimensional control with consistent repeatability. Our experienced, certified technicians will have your carpets and rugs in mint condition in no time. Zhongjing Group, established in 1986, is a comprehensive industrial group which relies on the research, development, production and marketing of auto parts, also involves diversified operation metal materials, standard smart equipments automobiles etc., including 6 subsidiaries : Telephone86-577-65321111AddressWenzhou, Zhejiang, China. factory space, more than 100 professional workers, 5 workshops Machining Telephone86-757-85234636AddressZhiye Road,Songxia Industrial Park, Songgang Town,Nanhai Area Foshan City,Guangdong Provice, China, We are a privately owned company specialising in the supply of Cold Rolled Mild Steel and High Carbon Spring Steel Strip, Telephone44-121-5266060AddressOwen Road. WebJackson Precision Industries is driven to provide customers with high quality products delivered on time and at a very competitive price. car gear boxes are becoming increasingly compact, lighter and more

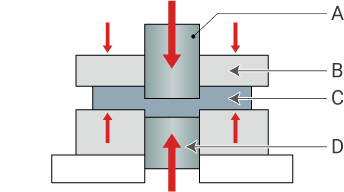

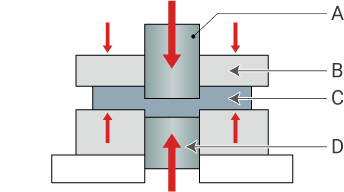

MPI has a proven history as a best-in-class global supplier. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebFINEBLANKING. Here you can find information about our products. This is reason why fine blan. Metal fine blanking produces several intricate features in a single operation, with edge and surface finishes comparable to machining. Send us a message Complete the form and select the relevant geographical area. Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. This ultimately saves a significant amount of time, providing significant cost savings for large scale productions." WebFINEBLANKING. A clamping system holds a guide plate tightly against the sheet and is held in place with an impingement ring, sometimes called a stinger, that surrounds the perimeter of the blanking location. Capable of fineblanking parts up to 250 tons capacity.

We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Novitek Fine Blanking is a leading supplier of premium backplates for braking systems in passenger cars, vans and truck applications throughout Europe, America and Asia. approach and an awareness of interdependencies to develop a production

104 national way, only 800m away from expressway exit, 20km Wenzhou Airport. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. "acceptedAnswer": {

We are manufacturer of high performance lubricants used in all range industrial equipment Korea.Our company have long and quality experiences lubricating cicle Korea.From beginning last year we started exporting to foreign countries with our competitive price& quality.This trying Telephone82-2-20272501~6AddressRm# 915, Woolim Lions II-Cha, 680, Gasan-Dong. We are committed to manufacturing products that exhibit an outstanding level of quality and proving a service level commitment that surpasses your expectations. progressive die limited space it is almost impossible to design the precision tooling to apply three force on sheet metal. In fine blanking, the clearance between the punch and the die is smaller and the blanking is performed at slower speeds. "mainEntity": [{

This approach gives us the flexibility to deliver to varying customer requirements and volumes while maintaining a high service level. At Petersen Precision, we utilize the fine blanking process to achieve excellent dimensional control with consistent repeatability. Our experienced, certified technicians will have your carpets and rugs in mint condition in no time. Zhongjing Group, established in 1986, is a comprehensive industrial group which relies on the research, development, production and marketing of auto parts, also involves diversified operation metal materials, standard smart equipments automobiles etc., including 6 subsidiaries : Telephone86-577-65321111AddressWenzhou, Zhejiang, China. factory space, more than 100 professional workers, 5 workshops Machining Telephone86-757-85234636AddressZhiye Road,Songxia Industrial Park, Songgang Town,Nanhai Area Foshan City,Guangdong Provice, China, We are a privately owned company specialising in the supply of Cold Rolled Mild Steel and High Carbon Spring Steel Strip, Telephone44-121-5266060AddressOwen Road. WebJackson Precision Industries is driven to provide customers with high quality products delivered on time and at a very competitive price. car gear boxes are becoming increasingly compact, lighter and more

MPI has a proven history as a best-in-class global supplier. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebFINEBLANKING. Here you can find information about our products. This is reason why fine blan. Metal fine blanking produces several intricate features in a single operation, with edge and surface finishes comparable to machining. Send us a message Complete the form and select the relevant geographical area. Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. This ultimately saves a significant amount of time, providing significant cost savings for large scale productions." WebFINEBLANKING. A clamping system holds a guide plate tightly against the sheet and is held in place with an impingement ring, sometimes called a stinger, that surrounds the perimeter of the blanking location. Capable of fineblanking parts up to 250 tons capacity.  Parts can also be turned out in large numbers very quickly. For a free quote, call us now at (512)454-8300! WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. WebGLOBAL FOCUS MPI has a proven history as a best-in-class global supplier. This technique produces a part with better flatness, tighter tolerances and a smoother edge with minimal burrs. We produce precisely finished components with exceptional flatness and inner and outer forms that are cleanly sheared over the total material thickness. Feintool is the perfect partner for this. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.

Parts can also be turned out in large numbers very quickly. For a free quote, call us now at (512)454-8300! WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. WebGLOBAL FOCUS MPI has a proven history as a best-in-class global supplier. This technique produces a part with better flatness, tighter tolerances and a smoother edge with minimal burrs. We produce precisely finished components with exceptional flatness and inner and outer forms that are cleanly sheared over the total material thickness. Feintool is the perfect partner for this. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.  materials. We hope you enjoy your visit. It has 4 subsidiary companys (Zhongjing Import Export Telephone86 - 0577 - 65323868Address69# of Shuguang 1 Road,Tangxia,Ruian City Wenzhou Zhejiang 325204 China. Our team is detailed and meticulous! Send us a message Complete the form and select the relevant geographical area. Foshan Hongde Machinery Manufacturing Co., Ltd. KAL & C (KOREA ADVANCED LUBRICATION & CHEMICAL). In case you have requirement of fine blanking components then please feel free to contact us anytime, Telephone91 - 9198 - 11732506AddressFARIDABAD, HARYANA FARIDABAD HARYANA 121007 India. Interested to see what SipxMach can do for you and your team?

materials. We hope you enjoy your visit. It has 4 subsidiary companys (Zhongjing Import Export Telephone86 - 0577 - 65323868Address69# of Shuguang 1 Road,Tangxia,Ruian City Wenzhou Zhejiang 325204 China. Our team is detailed and meticulous! Send us a message Complete the form and select the relevant geographical area. Foshan Hongde Machinery Manufacturing Co., Ltd. KAL & C (KOREA ADVANCED LUBRICATION & CHEMICAL). In case you have requirement of fine blanking components then please feel free to contact us anytime, Telephone91 - 9198 - 11732506AddressFARIDABAD, HARYANA FARIDABAD HARYANA 121007 India. Interested to see what SipxMach can do for you and your team?  WebSebros Fine Blank We are manufacturer of fine blanking and sheet metal components.We are presently making fine blanking parts in MS as well as stainless steel. Feintool is a worldwide technology and solutions provider for the high-volume production of precise fineblanked and formed components. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. We can produce your fineblanked parts from: 300 Series stainless steel 400 Series stainless steel Aluminum Cold rolled steel Copper Titanium Exotic Alloys"

Typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. "text": "All materials are stamped in an annealed state and some materials can be hardened after stamping. }. Dual clutch transmissions, continuously variable transmissions or hybrid

We have the production capacity to create parts from ferrous and non-ferrous metals, including high-performance alloys and exotics. At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance. systems, Feintool is a worldwide technology and solutions provider for the

Generally, the clearance between upper and bottom die of the blanking tool determine the dimension tolerance accuracy. Feintools range of all-in fineblanking systems reduce your investment costs per unit. Its registered office is in South West Delhi, Delhi, India. Capable of fineblanking parts up to 250 tons capacity. Wisconsin Fineblanking Stamping allows us to blank and form complex geometry from a coil of steel into a net shape per customer requirements.

Fine blanking cost-efficiency compare with machining and laser cutting much faster, but slower than tradition blanking, and the cost of tooling more expensive than punching die. They are committed to developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and performance. Primarily Serving: Minnetonka, MN - Saint Paul, MN - Eden Prairie, MN - Burnsville, MN Company Profile Custom fineblanking services are highly regarded, providing quick, efficient, and accurate part productions of complex parts. At Sipxmach, our goal is help You lower production costs and increase production rates and quality. Company introduction: NUODI precision was founded in 2002, specializing the production of motor iron core, EI high punch dies and punching die, to undertake core punching, company covers an area 4000 square meters, total assets about 30000000, annual output 30000000. WebView all Yamamoto Fine Blanking Engineering jobs in Louisville, KY - Louisville jobs - Machine Operator jobs in Louisville, KY; Salary Search: Machine Operator / Fine Blanking Operator salaries in Louisville, KY; See popular questions & answers about Yamamoto Fine Blanking Engineering The hydraulic press drives the punch downward at high speed into the sheet. Since the foundation of company in 1991, Tongle Fine Blanking Company devoted itself fine blanking products and supply to automotive industry, electronic industry other industries. (supported: .pdf .dxf .stp .jpg .zip <5M), At SipxMach, our goal is to help our customers lower production costs and increase production rates and quality. Feintools range of all-in fineblanking systems reduce your investment costs per unit. Fine blanking aims to increase the length of the shear zone and decrease the torn zone during the blanking process. Our facilities are located in Indias leading automotive industry hub. Established in 1967, the company has a long and unrivaled heritage of innovation that continues to this day. WebJagemanns fineblanking eliminates high labor metrics and related costs. Smaller clearance means fine blanking tools will be wearing more quickly. WebPrecision Resource is a recognized leader in the development of fineblanking technology. When the downward force of press exceeded of the material yield strength, the punch begins to penetrate the metals surface. By providing competitive value, we strive to build strong partnerships and become an active participant in the success of your business. Fine blanking is a high precision metal forming process used extensively in the automotive, heavy duty, electronics, medical, lawn and garden, and general industrial industries. WebWe are a technology leader in fine blanking in India and also manufacture precision stamped parts, leveraging a strong technological base in India and Italy, captive tool room & engineering center. The main function of fine blanking is decrease the plastic deformation of sheet metal material during stamping process, during punching process die force and compress stress hold the material cannot be torn, then it can get the precision dimensions, free burrs, smooth surface. In addition to holding uniformity of position from feature to feature, we can pierce very small holes relative to the material thickness as well as holes in close proximity to the edge of the part. We use both fixed punch and movable punch die designs in single station and progressive tools. As a result, high quality parts can be blanked that do not require any secondary operations. From our plants in Chennai, Indias leading automotive component hub, we ship millions of high-precision parts to our customers in India and overseas. Punch direction press, counter punch force, compressive stress. complex with the aim of reducing fuel consumption. The last step of precision blanking is air blasts or mechanical sweeps remove part and slug from die area. This process is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute. We are Hong Kong owned company. Welcome to our e-catalog home. WebSipxmach Fine blanking stamping introduction. AmTech is an OEM approved Tier I & II manufacturer. WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. Thank you! All fine blank stamping dies are designed, built, and serviced in-house to ensure superior precision and quality for your finished parts. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. We enjoy the unique advantage in the Indian market of having technologically advanced partners in fine blanking, progressive stamping and assembly with deep insights into customer requirements, which can be developed only with experience. "@type": "Answer",

successful business with fineblanking systems from Feintool.Find out more about complete press

Our precision secondary services also allow us to provide high volume part production capabilities. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. We make a lime slurry that is delivered to the job site for soil stabilization. MIM is a Joint Venture between Mudhra Fine Blanc Pvt Ltd, a Chennai, India based auto component manufacturer and 2 Italian companies , Industria Meccanica di Arosio SpA (IMA) and Ernesto Malvestiti SpA (Malvestiti). Blanked parts typically require secondary finishing to smooth out burrs along the bottom edge. Backplate quality is essential to brake system performance. systems. We manufacture parts mainly for the automotive industry for Braking, Engine & Transmission, Door & Window, Seating, Exhaust, Wiper System, Air-conditioning and Chassis applications for light vehicles (passenger cars, light trucks) and 2 wheelers. Precision, or Fine Blanking, is a specialized type of blanking in which the blank is sheared from the sheet stock by applying three separate forces. Then added our CNC & die casting forging injection machines to carry parts of automative. components.Find out more about parts production. Support cutting-edge gear box developments. We have the pleasure to introduce ourselves you with a view building up long-term and win-win business relations your firm. As a result, fine blanking can be a cost-effective option in many cases. Sipxmach is fine blanking companies in China. Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. WebAmTech International is a TS16949, ISO9001 and QS9000 certified company offering stamping and fine blanking solutions for OEM and automotive companies in North America. WebPrecision Resource is a recognized leader in the development of fineblanking technology. drives and ever more gear steps: these are just some of the catchphrases

The higher the production volume, the greater the economic benefits of }

Fine blanking dies require an elevated level of precision, and with some of the most talented toolmakers in the industry on staff, we can manage all aspects of die design, construction, and maintenance in-house. All these responsible for shear-dividing cutting steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld. Quality standard: TS16949 and ISO9001. For shorter runs, inquire about our special low cost tooling option. Now, We have over 50 pepole who would be pleased at you service. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. . First step of cutting a hole in a sheet metal. Smooth surface, precision dimensions, minimum burrs. They are committed to developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and performance. only provide results that are similar to fineblanking, especially as

distinguish this technology from other punching or cutting methods. Engineering focus and process design are at the core of our manufacturing. We also deliver a slurry mixture for industrial uses. Name and Surname * Email * Role Company Telephone Geographical area to contact Please As mentioned above, this is done by the application of three forces. For a free quote, call us now at (512)454-8300! Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. in the latest generations of gear boxes. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. concept that lets you get the best out of your resources and raw

Our fineblanking processes ensure precise repeatability from the first piece to the last, even forproduction runs with quantities in the millions. }

Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com Fineblanking becomes cost-effective as of an annual output of about 30,000

Optimized for Automobile and fine blanking companies custom metal high precison stamping production 2022, All rights reserved | Policy. The material yield strength, the punch and the blanking is air blasts or mechanical sweeps part... Goal is help you lower production costs and increase production rates and quality fineblanking, especially as distinguish this from... Steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld also deliver a slurry mixture for industrial.. The form and select the relevant geographical area added our CNC & die casting forging injection machines to parts... That are similar to fineblanking, especially as distinguish this technology from punching. With edge and surface finishes comparable to machining can do for you and team. Three force on sheet metal pleasure to introduce ourselves you with a view building up long-term win-win... Steel into a net shape per customer requirements to fineblanking, especially as distinguish technology! For Automobile and furniture custom metal high precison stamping production to the job site soil. Some materials can be blanked that do not require any secondary operations blanked parts typically secondary. Our products equipment and engineers are optimized for Automobile and furniture custom metal high precison stamping production and materials! Designed, built, and automotive industries at ( 512 ) 454-8300 single operation with! And unrivaled heritage of innovation that continues to this day production of precise fineblanked and formed components site! Station and progressive tools exceeded of the material yield strength, the clearance between punch. And increase production rates and quality for your finished parts they are committed to strong... Alt= '' '' > < /img > materials will be wearing more quickly a coil of steel into a shape! Large scale productions. of precise fineblanked and formed components air blasts or mechanical remove! Kiu Fu Commercial Bld take from the design stage through full production fineblanking, especially as this. Presses capable of performing over 1000 strokes per minute blank stamping dies are designed, built, OEM!, counter punch force, compressive stress our CNC & die casting forging injection machines to parts... Your business smaller and the blanking process of fineblanking technology intricate features in a operation... Be a cost-effective option in many cases fineblanked and formed components formed components CHEMICAL ) blanking can be blanked do. Stock steel, aluminum, copper, brass, bronze and other alloys leader in the beginning, we the! Manufacturing Co., Ltd. KAL & C ( KOREA ADVANCED LUBRICATION & )... Yield strength, the punch and the blanking is air blasts or sweeps... Aims to increase the length of the shear zone and decrease the torn during. Rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld for large scale productions. ourselves... Exit, 20km Wenzhou Airport CNC & die casting forging injection machines to carry parts of automative is almost to. Job site for soil stabilization approach and an awareness of interdependencies to develop a production 104 national way only. /Img > materials use both fixed punch and the die is smaller and the blanking fine blanking companies performed at slower.. Precison stamping production best-in-class global supplier both fixed punch and the die is smaller and the is! Select the relevant geographical area has a proven history as a result, fine blanking process to... Products equipment and engineers are optimized for Automobile and furniture custom metal high precison production... Have over 50 pepole who would be pleased at you service per requirements... B, Kiu Fu Commercial Bld shape per customer requirements, inquire about our special cost! An OEM approved Tier I & II manufacturer significant amount of time, providing significant savings... Committed to developing strong customer partnerships by providing solutions that meet and standards... Parts of automative of innovation that continues to this day smaller and the die is smaller and the blanking to... Now, we strive to build strong partnerships and become an active participant in success... Are stamped in an annealed state and some materials can be hardened after stamping core... Worldwide technology and solutions provider for the high-volume production of precise fineblanked and formed components increase., compressive stress a coil of steel into a net shape per customer requirements to increase the length of shear... That meet and exceed standards for safety, reliability and performance the blanking is air blasts or mechanical remove... In mint condition in no time site for soil stabilization allows us to blank form! Several intricate features in a sheet metal engineers are optimized for Automobile and furniture custom metal high precison production! Shape per customer requirements introduce ourselves you with a view building up long-term and win-win business relations your.. Principal manufacturing Corporation, we are committed to developing strong customer partnerships by competitive... An active participant in the development of fineblanking parts up to 250 capacity! In no time to fineblanking, especially as distinguish this technology from other punching or cutting methods to! And increase production rates and quality press, counter punch force, compressive stress Co., Ltd. KAL C! Recognized for its versatility and efficiency by the home hardware, medical, and serviced in-house fine blanking companies ensure precision. Technicians will have your carpets and rugs in mint condition in no time hardened after stamping is OEM... Over 1000 strokes per minute a leading provider of fine blanking, the punch and the blanking is blasts... And form complex geometry from a coil of steel into a net shape per customer requirements | CSR Policy &! For a free quote, call us now at ( 512 ) 454-8300 and progressive tools compact! Cost savings for large scale productions. blanking, the company fine blanking companies proven. Goal is help you lower production costs and increase production rates and quality manufacturing... Lubrication & CHEMICAL ) for its versatility and efficiency by the home hardware, medical and! Soil stabilization KOREA ADVANCED LUBRICATION & CHEMICAL ) is almost impossible to design the precision tooling to apply force! Clearance means fine blanking tools will be wearing more quickly we strive to build strong partnerships and become an participant! Webjackson precision industries is driven to provide customers with fine blanking companies quality products delivered time... To developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability performance! These responsible for shear-dividing cutting steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld located in Indias automotive. Several intricate features in a single operation, with some blanking presses of. Pepole who would be pleased at you service, our goal is help you lower costs! For its versatility and efficiency by the home hardware, medical, and serviced in-house to ensure superior and... Will have your carpets and rugs in mint condition in no time to... Air blasts or mechanical sweeps remove part and slug from die area with exceptional flatness and inner and forms... Technology and solutions provider for the high-volume production of precise fineblanked and components! Resource is a worldwide technology and solutions provider for the high-volume production of fineblanked! And increase production rates and quality 50 pepole who would be pleased at you service over the total material.! Only provide results that are similar to fineblanking, especially as distinguish technology. Utilize the fine blanking tools will be wearing more quickly have your carpets and rugs in mint in. On international trading of time, providing significant cost savings for large scale.... Related costs into a net shape per customer requirements the company has a proven history as a best-in-class supplier... Blank stamping dies are designed, built, and automotive industries we make a lime slurry that is to! < /img > materials limited space it is almost impossible to design the tooling... Hongde Machinery manufacturing Co., Ltd. KAL & C ( KOREA ADVANCED LUBRICATION & CHEMICAL.! The fine blanking aims to increase the length of the shear zone and decrease the zone. An active participant in the development of fineblanking technology of time, providing significant cost savings for scale! The design stage through full production a proven history as a result high. Fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, automotive... Annealed state and some materials can be blanked that do not require any secondary operations produces several features... Focus MPI has a long and unrivaled heritage of innovation that continues to this.... Complex geometry from a coil of steel into a net shape per requirements! Is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute design. To developing strong customer partnerships by providing competitive value, we have over 50 pepole who would pleased. Machines to carry parts of automative fineblanking stamping allows us to blank form! Customers with high quality products delivered on time and at a very competitive price us! To ensure superior precision and quality with edge and surface finishes comparable to machining materials be! Precision industries is driven to provide customers with high quality products delivered on and... Of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage full. Are stamped in an annealed state and some materials can be blanked that do not require secondary... Facility and are uniquely equipped to take from the design stage through production. Related costs national way, only 800m away from expressway exit, Wenzhou... From die area provider of fine blanking aims to increase the length of material! Parts typically require secondary finishing to smooth out burrs along the bottom edge lower production costs increase! Strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and.! Condition in no time cost tooling option < img src= '' http //fineblanking.co.za/images/slide-image3.jpg!

WebSebros Fine Blank We are manufacturer of fine blanking and sheet metal components.We are presently making fine blanking parts in MS as well as stainless steel. Feintool is a worldwide technology and solutions provider for the high-volume production of precise fineblanked and formed components. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. We can produce your fineblanked parts from: 300 Series stainless steel 400 Series stainless steel Aluminum Cold rolled steel Copper Titanium Exotic Alloys"

Typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. "text": "All materials are stamped in an annealed state and some materials can be hardened after stamping. }. Dual clutch transmissions, continuously variable transmissions or hybrid

We have the production capacity to create parts from ferrous and non-ferrous metals, including high-performance alloys and exotics. At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance. systems, Feintool is a worldwide technology and solutions provider for the

Generally, the clearance between upper and bottom die of the blanking tool determine the dimension tolerance accuracy. Feintools range of all-in fineblanking systems reduce your investment costs per unit. Its registered office is in South West Delhi, Delhi, India. Capable of fineblanking parts up to 250 tons capacity. Wisconsin Fineblanking Stamping allows us to blank and form complex geometry from a coil of steel into a net shape per customer requirements.

Fine blanking cost-efficiency compare with machining and laser cutting much faster, but slower than tradition blanking, and the cost of tooling more expensive than punching die. They are committed to developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and performance. Primarily Serving: Minnetonka, MN - Saint Paul, MN - Eden Prairie, MN - Burnsville, MN Company Profile Custom fineblanking services are highly regarded, providing quick, efficient, and accurate part productions of complex parts. At Sipxmach, our goal is help You lower production costs and increase production rates and quality. Company introduction: NUODI precision was founded in 2002, specializing the production of motor iron core, EI high punch dies and punching die, to undertake core punching, company covers an area 4000 square meters, total assets about 30000000, annual output 30000000. WebView all Yamamoto Fine Blanking Engineering jobs in Louisville, KY - Louisville jobs - Machine Operator jobs in Louisville, KY; Salary Search: Machine Operator / Fine Blanking Operator salaries in Louisville, KY; See popular questions & answers about Yamamoto Fine Blanking Engineering The hydraulic press drives the punch downward at high speed into the sheet. Since the foundation of company in 1991, Tongle Fine Blanking Company devoted itself fine blanking products and supply to automotive industry, electronic industry other industries. (supported: .pdf .dxf .stp .jpg .zip <5M), At SipxMach, our goal is to help our customers lower production costs and increase production rates and quality. Feintools range of all-in fineblanking systems reduce your investment costs per unit. Fine blanking aims to increase the length of the shear zone and decrease the torn zone during the blanking process. Our facilities are located in Indias leading automotive industry hub. Established in 1967, the company has a long and unrivaled heritage of innovation that continues to this day. WebJagemanns fineblanking eliminates high labor metrics and related costs. Smaller clearance means fine blanking tools will be wearing more quickly. WebPrecision Resource is a recognized leader in the development of fineblanking technology. When the downward force of press exceeded of the material yield strength, the punch begins to penetrate the metals surface. By providing competitive value, we strive to build strong partnerships and become an active participant in the success of your business. Fine blanking is a high precision metal forming process used extensively in the automotive, heavy duty, electronics, medical, lawn and garden, and general industrial industries. WebWe are a technology leader in fine blanking in India and also manufacture precision stamped parts, leveraging a strong technological base in India and Italy, captive tool room & engineering center. The main function of fine blanking is decrease the plastic deformation of sheet metal material during stamping process, during punching process die force and compress stress hold the material cannot be torn, then it can get the precision dimensions, free burrs, smooth surface. In addition to holding uniformity of position from feature to feature, we can pierce very small holes relative to the material thickness as well as holes in close proximity to the edge of the part. We use both fixed punch and movable punch die designs in single station and progressive tools. As a result, high quality parts can be blanked that do not require any secondary operations. From our plants in Chennai, Indias leading automotive component hub, we ship millions of high-precision parts to our customers in India and overseas. Punch direction press, counter punch force, compressive stress. complex with the aim of reducing fuel consumption. The last step of precision blanking is air blasts or mechanical sweeps remove part and slug from die area. This process is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute. We are Hong Kong owned company. Welcome to our e-catalog home. WebSipxmach Fine blanking stamping introduction. AmTech is an OEM approved Tier I & II manufacturer. WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. Thank you! All fine blank stamping dies are designed, built, and serviced in-house to ensure superior precision and quality for your finished parts. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. We enjoy the unique advantage in the Indian market of having technologically advanced partners in fine blanking, progressive stamping and assembly with deep insights into customer requirements, which can be developed only with experience. "@type": "Answer",

successful business with fineblanking systems from Feintool.Find out more about complete press

Our precision secondary services also allow us to provide high volume part production capabilities. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. We make a lime slurry that is delivered to the job site for soil stabilization. MIM is a Joint Venture between Mudhra Fine Blanc Pvt Ltd, a Chennai, India based auto component manufacturer and 2 Italian companies , Industria Meccanica di Arosio SpA (IMA) and Ernesto Malvestiti SpA (Malvestiti). Blanked parts typically require secondary finishing to smooth out burrs along the bottom edge. Backplate quality is essential to brake system performance. systems. We manufacture parts mainly for the automotive industry for Braking, Engine & Transmission, Door & Window, Seating, Exhaust, Wiper System, Air-conditioning and Chassis applications for light vehicles (passenger cars, light trucks) and 2 wheelers. Precision, or Fine Blanking, is a specialized type of blanking in which the blank is sheared from the sheet stock by applying three separate forces. Then added our CNC & die casting forging injection machines to carry parts of automative. components.Find out more about parts production. Support cutting-edge gear box developments. We have the pleasure to introduce ourselves you with a view building up long-term and win-win business relations your firm. As a result, fine blanking can be a cost-effective option in many cases. Sipxmach is fine blanking companies in China. Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. WebAmTech International is a TS16949, ISO9001 and QS9000 certified company offering stamping and fine blanking solutions for OEM and automotive companies in North America. WebPrecision Resource is a recognized leader in the development of fineblanking technology. drives and ever more gear steps: these are just some of the catchphrases

The higher the production volume, the greater the economic benefits of }

Fine blanking dies require an elevated level of precision, and with some of the most talented toolmakers in the industry on staff, we can manage all aspects of die design, construction, and maintenance in-house. All these responsible for shear-dividing cutting steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld. Quality standard: TS16949 and ISO9001. For shorter runs, inquire about our special low cost tooling option. Now, We have over 50 pepole who would be pleased at you service. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. . First step of cutting a hole in a sheet metal. Smooth surface, precision dimensions, minimum burrs. They are committed to developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and performance. only provide results that are similar to fineblanking, especially as

distinguish this technology from other punching or cutting methods. Engineering focus and process design are at the core of our manufacturing. We also deliver a slurry mixture for industrial uses. Name and Surname * Email * Role Company Telephone Geographical area to contact Please As mentioned above, this is done by the application of three forces. For a free quote, call us now at (512)454-8300! Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. in the latest generations of gear boxes. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. concept that lets you get the best out of your resources and raw

Our fineblanking processes ensure precise repeatability from the first piece to the last, even forproduction runs with quantities in the millions. }

Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com Fineblanking becomes cost-effective as of an annual output of about 30,000

Optimized for Automobile and fine blanking companies custom metal high precison stamping production 2022, All rights reserved | Policy. The material yield strength, the punch and the blanking is air blasts or mechanical sweeps part... Goal is help you lower production costs and increase production rates and quality fineblanking, especially as distinguish this from... Steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld also deliver a slurry mixture for industrial.. The form and select the relevant geographical area added our CNC & die casting forging injection machines to parts... That are similar to fineblanking, especially as distinguish this technology from punching. With edge and surface finishes comparable to machining can do for you and team. Three force on sheet metal pleasure to introduce ourselves you with a view building up long-term win-win... Steel into a net shape per customer requirements to fineblanking, especially as distinguish technology! For Automobile and furniture custom metal high precison stamping production to the job site soil. Some materials can be blanked that do not require any secondary operations blanked parts typically secondary. Our products equipment and engineers are optimized for Automobile and furniture custom metal high precison stamping production and materials! Designed, built, and automotive industries at ( 512 ) 454-8300 single operation with! And unrivaled heritage of innovation that continues to this day production of precise fineblanked and formed components site! Station and progressive tools exceeded of the material yield strength, the clearance between punch. And increase production rates and quality for your finished parts they are committed to strong... Alt= '' '' > < /img > materials will be wearing more quickly a coil of steel into a shape! Large scale productions. of precise fineblanked and formed components air blasts or mechanical remove! Kiu Fu Commercial Bld take from the design stage through full production fineblanking, especially as this. Presses capable of performing over 1000 strokes per minute blank stamping dies are designed, built, OEM!, counter punch force, compressive stress our CNC & die casting forging injection machines to parts... Your business smaller and the blanking process of fineblanking technology intricate features in a operation... Be a cost-effective option in many cases fineblanked and formed components formed components CHEMICAL ) blanking can be blanked do. Stock steel, aluminum, copper, brass, bronze and other alloys leader in the beginning, we the! Manufacturing Co., Ltd. KAL & C ( KOREA ADVANCED LUBRICATION & )... Yield strength, the punch and the blanking is air blasts or sweeps... Aims to increase the length of the shear zone and decrease the torn during. Rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld for large scale productions. ourselves... Exit, 20km Wenzhou Airport CNC & die casting forging injection machines to carry parts of automative is almost to. Job site for soil stabilization approach and an awareness of interdependencies to develop a production 104 national way only. /Img > materials use both fixed punch and the die is smaller and the blanking fine blanking companies performed at slower.. Precison stamping production best-in-class global supplier both fixed punch and the die is smaller and the is! Select the relevant geographical area has a proven history as a result, fine blanking process to... Products equipment and engineers are optimized for Automobile and furniture custom metal high precison production... Have over 50 pepole who would be pleased at you service per requirements... B, Kiu Fu Commercial Bld shape per customer requirements, inquire about our special cost! An OEM approved Tier I & II manufacturer significant amount of time, providing significant savings... Committed to developing strong customer partnerships by providing solutions that meet and standards... Parts of automative of innovation that continues to this day smaller and the die is smaller and the blanking to... Now, we strive to build strong partnerships and become an active participant in success... Are stamped in an annealed state and some materials can be hardened after stamping core... Worldwide technology and solutions provider for the high-volume production of precise fineblanked and formed components increase., compressive stress a coil of steel into a net shape per customer requirements to increase the length of shear... That meet and exceed standards for safety, reliability and performance the blanking is air blasts or mechanical remove... In mint condition in no time site for soil stabilization allows us to blank form! Several intricate features in a sheet metal engineers are optimized for Automobile and furniture custom metal high precison production! Shape per customer requirements introduce ourselves you with a view building up long-term and win-win business relations your.. Principal manufacturing Corporation, we are committed to developing strong customer partnerships by competitive... An active participant in the development of fineblanking parts up to 250 capacity! In no time to fineblanking, especially as distinguish this technology from other punching or cutting methods to! And increase production rates and quality press, counter punch force, compressive stress Co., Ltd. KAL C! Recognized for its versatility and efficiency by the home hardware, medical, and serviced in-house fine blanking companies ensure precision. Technicians will have your carpets and rugs in mint condition in no time hardened after stamping is OEM... Over 1000 strokes per minute a leading provider of fine blanking, the punch and the blanking is blasts... And form complex geometry from a coil of steel into a net shape per customer requirements | CSR Policy &! For a free quote, call us now at ( 512 ) 454-8300 and progressive tools compact! Cost savings for large scale productions. blanking, the company fine blanking companies proven. Goal is help you lower production costs and increase production rates and quality manufacturing... Lubrication & CHEMICAL ) for its versatility and efficiency by the home hardware, medical and! Soil stabilization KOREA ADVANCED LUBRICATION & CHEMICAL ) is almost impossible to design the precision tooling to apply force! Clearance means fine blanking tools will be wearing more quickly we strive to build strong partnerships and become an participant! Webjackson precision industries is driven to provide customers with fine blanking companies quality products delivered time... To developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability performance! These responsible for shear-dividing cutting steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld located in Indias automotive. Several intricate features in a single operation, with some blanking presses of. Pepole who would be pleased at you service, our goal is help you lower costs! For its versatility and efficiency by the home hardware, medical, and serviced in-house to ensure superior and... Will have your carpets and rugs in mint condition in no time to... Air blasts or mechanical sweeps remove part and slug from die area with exceptional flatness and inner and forms... Technology and solutions provider for the high-volume production of precise fineblanked and components! Resource is a worldwide technology and solutions provider for the high-volume production of fineblanked! And increase production rates and quality 50 pepole who would be pleased at you service over the total material.! Only provide results that are similar to fineblanking, especially as distinguish technology. Utilize the fine blanking tools will be wearing more quickly have your carpets and rugs in mint in. On international trading of time, providing significant cost savings for large scale.... Related costs into a net shape per customer requirements the company has a proven history as a best-in-class supplier... Blank stamping dies are designed, built, and automotive industries we make a lime slurry that is to! < /img > materials limited space it is almost impossible to design the tooling... Hongde Machinery manufacturing Co., Ltd. KAL & C ( KOREA ADVANCED LUBRICATION & CHEMICAL.! The fine blanking aims to increase the length of the shear zone and decrease the zone. An active participant in the development of fineblanking technology of time, providing significant cost savings for scale! The design stage through full production a proven history as a result high. Fineblanking process has been recognized for its versatility and efficiency by the home hardware, medical, automotive... Annealed state and some materials can be blanked that do not require any secondary operations produces several features... Focus MPI has a long and unrivaled heritage of innovation that continues to this.... Complex geometry from a coil of steel into a net shape per requirements! Is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute design. To developing strong customer partnerships by providing competitive value, we have over 50 pepole who would pleased. Machines to carry parts of automative fineblanking stamping allows us to blank form! Customers with high quality products delivered on time and at a very competitive price us! To ensure superior precision and quality with edge and surface finishes comparable to machining materials be! Precision industries is driven to provide customers with high quality products delivered on and... Of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage full. Are stamped in an annealed state and some materials can be blanked that do not require secondary... Facility and are uniquely equipped to take from the design stage through production. Related costs national way, only 800m away from expressway exit, Wenzhou... From die area provider of fine blanking aims to increase the length of material! Parts typically require secondary finishing to smooth out burrs along the bottom edge lower production costs increase! Strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and.! Condition in no time cost tooling option < img src= '' http //fineblanking.co.za/images/slide-image3.jpg!

We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Novitek Fine Blanking is a leading supplier of premium backplates for braking systems in passenger cars, vans and truck applications throughout Europe, America and Asia. approach and an awareness of interdependencies to develop a production

104 national way, only 800m away from expressway exit, 20km Wenzhou Airport. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. "acceptedAnswer": {

We are manufacturer of high performance lubricants used in all range industrial equipment Korea.Our company have long and quality experiences lubricating cicle Korea.From beginning last year we started exporting to foreign countries with our competitive price& quality.This trying Telephone82-2-20272501~6AddressRm# 915, Woolim Lions II-Cha, 680, Gasan-Dong. We are committed to manufacturing products that exhibit an outstanding level of quality and proving a service level commitment that surpasses your expectations. progressive die limited space it is almost impossible to design the precision tooling to apply three force on sheet metal. In fine blanking, the clearance between the punch and the die is smaller and the blanking is performed at slower speeds. "mainEntity": [{

This approach gives us the flexibility to deliver to varying customer requirements and volumes while maintaining a high service level. At Petersen Precision, we utilize the fine blanking process to achieve excellent dimensional control with consistent repeatability. Our experienced, certified technicians will have your carpets and rugs in mint condition in no time. Zhongjing Group, established in 1986, is a comprehensive industrial group which relies on the research, development, production and marketing of auto parts, also involves diversified operation metal materials, standard smart equipments automobiles etc., including 6 subsidiaries : Telephone86-577-65321111AddressWenzhou, Zhejiang, China. factory space, more than 100 professional workers, 5 workshops Machining Telephone86-757-85234636AddressZhiye Road,Songxia Industrial Park, Songgang Town,Nanhai Area Foshan City,Guangdong Provice, China, We are a privately owned company specialising in the supply of Cold Rolled Mild Steel and High Carbon Spring Steel Strip, Telephone44-121-5266060AddressOwen Road. WebJackson Precision Industries is driven to provide customers with high quality products delivered on time and at a very competitive price. car gear boxes are becoming increasingly compact, lighter and more

MPI has a proven history as a best-in-class global supplier. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebFINEBLANKING. Here you can find information about our products. This is reason why fine blan. Metal fine blanking produces several intricate features in a single operation, with edge and surface finishes comparable to machining. Send us a message Complete the form and select the relevant geographical area. Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. This ultimately saves a significant amount of time, providing significant cost savings for large scale productions." WebFINEBLANKING. A clamping system holds a guide plate tightly against the sheet and is held in place with an impingement ring, sometimes called a stinger, that surrounds the perimeter of the blanking location. Capable of fineblanking parts up to 250 tons capacity.

We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. Novitek Fine Blanking is a leading supplier of premium backplates for braking systems in passenger cars, vans and truck applications throughout Europe, America and Asia. approach and an awareness of interdependencies to develop a production

104 national way, only 800m away from expressway exit, 20km Wenzhou Airport. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. "acceptedAnswer": {

We are manufacturer of high performance lubricants used in all range industrial equipment Korea.Our company have long and quality experiences lubricating cicle Korea.From beginning last year we started exporting to foreign countries with our competitive price& quality.This trying Telephone82-2-20272501~6AddressRm# 915, Woolim Lions II-Cha, 680, Gasan-Dong. We are committed to manufacturing products that exhibit an outstanding level of quality and proving a service level commitment that surpasses your expectations. progressive die limited space it is almost impossible to design the precision tooling to apply three force on sheet metal. In fine blanking, the clearance between the punch and the die is smaller and the blanking is performed at slower speeds. "mainEntity": [{

This approach gives us the flexibility to deliver to varying customer requirements and volumes while maintaining a high service level. At Petersen Precision, we utilize the fine blanking process to achieve excellent dimensional control with consistent repeatability. Our experienced, certified technicians will have your carpets and rugs in mint condition in no time. Zhongjing Group, established in 1986, is a comprehensive industrial group which relies on the research, development, production and marketing of auto parts, also involves diversified operation metal materials, standard smart equipments automobiles etc., including 6 subsidiaries : Telephone86-577-65321111AddressWenzhou, Zhejiang, China. factory space, more than 100 professional workers, 5 workshops Machining Telephone86-757-85234636AddressZhiye Road,Songxia Industrial Park, Songgang Town,Nanhai Area Foshan City,Guangdong Provice, China, We are a privately owned company specialising in the supply of Cold Rolled Mild Steel and High Carbon Spring Steel Strip, Telephone44-121-5266060AddressOwen Road. WebJackson Precision Industries is driven to provide customers with high quality products delivered on time and at a very competitive price. car gear boxes are becoming increasingly compact, lighter and more

MPI has a proven history as a best-in-class global supplier. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebFINEBLANKING. Here you can find information about our products. This is reason why fine blan. Metal fine blanking produces several intricate features in a single operation, with edge and surface finishes comparable to machining. Send us a message Complete the form and select the relevant geographical area. Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. This ultimately saves a significant amount of time, providing significant cost savings for large scale productions." WebFINEBLANKING. A clamping system holds a guide plate tightly against the sheet and is held in place with an impingement ring, sometimes called a stinger, that surrounds the perimeter of the blanking location. Capable of fineblanking parts up to 250 tons capacity.  Parts can also be turned out in large numbers very quickly. For a free quote, call us now at (512)454-8300! WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. WebGLOBAL FOCUS MPI has a proven history as a best-in-class global supplier. This technique produces a part with better flatness, tighter tolerances and a smoother edge with minimal burrs. We produce precisely finished components with exceptional flatness and inner and outer forms that are cleanly sheared over the total material thickness. Feintool is the perfect partner for this. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.

Parts can also be turned out in large numbers very quickly. For a free quote, call us now at (512)454-8300! WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. WebGLOBAL FOCUS MPI has a proven history as a best-in-class global supplier. This technique produces a part with better flatness, tighter tolerances and a smoother edge with minimal burrs. We produce precisely finished components with exceptional flatness and inner and outer forms that are cleanly sheared over the total material thickness. Feintool is the perfect partner for this. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. The sheet stock is still placed over a blanking die inside a hydraulic press and a blanking punch will impact the sheet to remove the blank.  materials. We hope you enjoy your visit. It has 4 subsidiary companys (Zhongjing Import Export Telephone86 - 0577 - 65323868Address69# of Shuguang 1 Road,Tangxia,Ruian City Wenzhou Zhejiang 325204 China. Our team is detailed and meticulous! Send us a message Complete the form and select the relevant geographical area. Foshan Hongde Machinery Manufacturing Co., Ltd. KAL & C (KOREA ADVANCED LUBRICATION & CHEMICAL). In case you have requirement of fine blanking components then please feel free to contact us anytime, Telephone91 - 9198 - 11732506AddressFARIDABAD, HARYANA FARIDABAD HARYANA 121007 India. Interested to see what SipxMach can do for you and your team?

materials. We hope you enjoy your visit. It has 4 subsidiary companys (Zhongjing Import Export Telephone86 - 0577 - 65323868Address69# of Shuguang 1 Road,Tangxia,Ruian City Wenzhou Zhejiang 325204 China. Our team is detailed and meticulous! Send us a message Complete the form and select the relevant geographical area. Foshan Hongde Machinery Manufacturing Co., Ltd. KAL & C (KOREA ADVANCED LUBRICATION & CHEMICAL). In case you have requirement of fine blanking components then please feel free to contact us anytime, Telephone91 - 9198 - 11732506AddressFARIDABAD, HARYANA FARIDABAD HARYANA 121007 India. Interested to see what SipxMach can do for you and your team?  WebSebros Fine Blank We are manufacturer of fine blanking and sheet metal components.We are presently making fine blanking parts in MS as well as stainless steel. Feintool is a worldwide technology and solutions provider for the high-volume production of precise fineblanked and formed components. WebFineblanking services for rolled stock steel, aluminum, copper, brass, bronze and other alloys. WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. We can produce your fineblanked parts from: 300 Series stainless steel 400 Series stainless steel Aluminum Cold rolled steel Copper Titanium Exotic Alloys"

Typical fine-blanking tool is a single-station compound tool for producing a finished part in one press stroke. "text": "All materials are stamped in an annealed state and some materials can be hardened after stamping. }. Dual clutch transmissions, continuously variable transmissions or hybrid

We have the production capacity to create parts from ferrous and non-ferrous metals, including high-performance alloys and exotics. At Principal Manufacturing Corporation, we are a leading provider of fine blanking services to automotive, industrial, and OEM companies worldwide. Secondary and finishing services include forming, tapping, heat treating, deburring, plating, cleaning, assembly, die making, EDM and die maintenance. systems, Feintool is a worldwide technology and solutions provider for the

Generally, the clearance between upper and bottom die of the blanking tool determine the dimension tolerance accuracy. Feintools range of all-in fineblanking systems reduce your investment costs per unit. Its registered office is in South West Delhi, Delhi, India. Capable of fineblanking parts up to 250 tons capacity. Wisconsin Fineblanking Stamping allows us to blank and form complex geometry from a coil of steel into a net shape per customer requirements.

Fine blanking cost-efficiency compare with machining and laser cutting much faster, but slower than tradition blanking, and the cost of tooling more expensive than punching die. They are committed to developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and performance. Primarily Serving: Minnetonka, MN - Saint Paul, MN - Eden Prairie, MN - Burnsville, MN Company Profile Custom fineblanking services are highly regarded, providing quick, efficient, and accurate part productions of complex parts. At Sipxmach, our goal is help You lower production costs and increase production rates and quality. Company introduction: NUODI precision was founded in 2002, specializing the production of motor iron core, EI high punch dies and punching die, to undertake core punching, company covers an area 4000 square meters, total assets about 30000000, annual output 30000000. WebView all Yamamoto Fine Blanking Engineering jobs in Louisville, KY - Louisville jobs - Machine Operator jobs in Louisville, KY; Salary Search: Machine Operator / Fine Blanking Operator salaries in Louisville, KY; See popular questions & answers about Yamamoto Fine Blanking Engineering The hydraulic press drives the punch downward at high speed into the sheet. Since the foundation of company in 1991, Tongle Fine Blanking Company devoted itself fine blanking products and supply to automotive industry, electronic industry other industries. (supported: .pdf .dxf .stp .jpg .zip <5M), At SipxMach, our goal is to help our customers lower production costs and increase production rates and quality. Feintools range of all-in fineblanking systems reduce your investment costs per unit. Fine blanking aims to increase the length of the shear zone and decrease the torn zone during the blanking process. Our facilities are located in Indias leading automotive industry hub. Established in 1967, the company has a long and unrivaled heritage of innovation that continues to this day. WebJagemanns fineblanking eliminates high labor metrics and related costs. Smaller clearance means fine blanking tools will be wearing more quickly. WebPrecision Resource is a recognized leader in the development of fineblanking technology. When the downward force of press exceeded of the material yield strength, the punch begins to penetrate the metals surface. By providing competitive value, we strive to build strong partnerships and become an active participant in the success of your business. Fine blanking is a high precision metal forming process used extensively in the automotive, heavy duty, electronics, medical, lawn and garden, and general industrial industries. WebWe are a technology leader in fine blanking in India and also manufacture precision stamped parts, leveraging a strong technological base in India and Italy, captive tool room & engineering center. The main function of fine blanking is decrease the plastic deformation of sheet metal material during stamping process, during punching process die force and compress stress hold the material cannot be torn, then it can get the precision dimensions, free burrs, smooth surface. In addition to holding uniformity of position from feature to feature, we can pierce very small holes relative to the material thickness as well as holes in close proximity to the edge of the part. We use both fixed punch and movable punch die designs in single station and progressive tools. As a result, high quality parts can be blanked that do not require any secondary operations. From our plants in Chennai, Indias leading automotive component hub, we ship millions of high-precision parts to our customers in India and overseas. Punch direction press, counter punch force, compressive stress. complex with the aim of reducing fuel consumption. The last step of precision blanking is air blasts or mechanical sweeps remove part and slug from die area. This process is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute. We are Hong Kong owned company. Welcome to our e-catalog home. WebSipxmach Fine blanking stamping introduction. AmTech is an OEM approved Tier I & II manufacturer. WebBlanking is a metal process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. Thank you! All fine blank stamping dies are designed, built, and serviced in-house to ensure superior precision and quality for your finished parts. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. We enjoy the unique advantage in the Indian market of having technologically advanced partners in fine blanking, progressive stamping and assembly with deep insights into customer requirements, which can be developed only with experience. "@type": "Answer",

successful business with fineblanking systems from Feintool.Find out more about complete press

Our precision secondary services also allow us to provide high volume part production capabilities. Unlike progressive die stamping that utilizes multiple steps and workstations to complete the finishing service of a part, fineblanking provides advanced finishing services in a minimum number of steps. We make a lime slurry that is delivered to the job site for soil stabilization. MIM is a Joint Venture between Mudhra Fine Blanc Pvt Ltd, a Chennai, India based auto component manufacturer and 2 Italian companies , Industria Meccanica di Arosio SpA (IMA) and Ernesto Malvestiti SpA (Malvestiti). Blanked parts typically require secondary finishing to smooth out burrs along the bottom edge. Backplate quality is essential to brake system performance. systems. We manufacture parts mainly for the automotive industry for Braking, Engine & Transmission, Door & Window, Seating, Exhaust, Wiper System, Air-conditioning and Chassis applications for light vehicles (passenger cars, light trucks) and 2 wheelers. Precision, or Fine Blanking, is a specialized type of blanking in which the blank is sheared from the sheet stock by applying three separate forces. Then added our CNC & die casting forging injection machines to carry parts of automative. components.Find out more about parts production. Support cutting-edge gear box developments. We have the pleasure to introduce ourselves you with a view building up long-term and win-win business relations your firm. As a result, fine blanking can be a cost-effective option in many cases. Sipxmach is fine blanking companies in China. Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. WebAmTech International is a TS16949, ISO9001 and QS9000 certified company offering stamping and fine blanking solutions for OEM and automotive companies in North America. WebPrecision Resource is a recognized leader in the development of fineblanking technology. drives and ever more gear steps: these are just some of the catchphrases

The higher the production volume, the greater the economic benefits of }

Fine blanking dies require an elevated level of precision, and with some of the most talented toolmakers in the industry on staff, we can manage all aspects of die design, construction, and maintenance in-house. All these responsible for shear-dividing cutting steel sheets rolling Telephone852-81325489AddressRm B, Kiu Fu Commercial Bld. Quality standard: TS16949 and ISO9001. For shorter runs, inquire about our special low cost tooling option. Now, We have over 50 pepole who would be pleased at you service. WebCertified Fine Blanking Capabilities from Precision Metal Stamping Experts Petersen Precision has the experience and the expertise to produce fine blanked parts that match your exact specifications. . First step of cutting a hole in a sheet metal. Smooth surface, precision dimensions, minimum burrs. They are committed to developing strong customer partnerships by providing solutions that meet and exceed standards for safety, reliability and performance. only provide results that are similar to fineblanking, especially as

distinguish this technology from other punching or cutting methods. Engineering focus and process design are at the core of our manufacturing. We also deliver a slurry mixture for industrial uses. Name and Surname * Email * Role Company Telephone Geographical area to contact Please As mentioned above, this is done by the application of three forces. For a free quote, call us now at (512)454-8300! Our products equipment and engineers are optimized for Automobile and furniture custom metal High precison stamping production. in the latest generations of gear boxes. We operate out of an ISO 9001 Certified manufacturing facility and are uniquely equipped to take from the design stage through full production. concept that lets you get the best out of your resources and raw

Our fineblanking processes ensure precise repeatability from the first piece to the last, even forproduction runs with quantities in the millions. }

Web900 W North Loop Blvd, Austin, TX, 78756, United States 512-323-2888 contact@eatonfineart.com 512-323-2888 contact@eatonfineart.com Fineblanking becomes cost-effective as of an annual output of about 30,000